Associate Professor Jayashree Arcot and Professor Martina Stenzel at UNSW Sydney were looking for ways to convert agricultural waste into something that could value add to the industry it came from while potentially solving problems for another.

A good contender was the banana growing industry which, according to A/Prof Arcot, produces large amounts of organic waste, with only 12% of the plant being used (the fruit) while the rest is discarded after harvest.

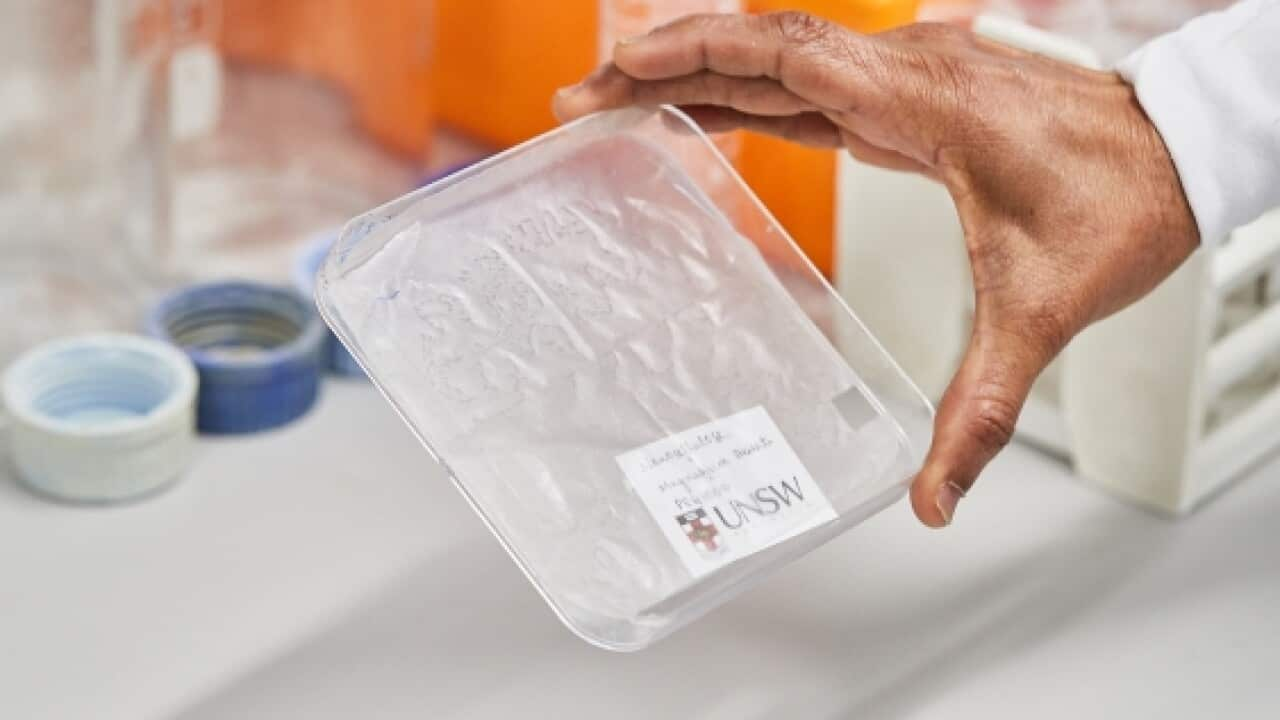

Using a reliable supply of pseudostem material from banana plants grown at the Royal Botanic Garden Sydney, A/Prof Arcot and Prof Stenzel (UNSW School of Chemistry) set to work in extracting cellulose to test its suitability as a packaging alternative. The duo finally made the material which has a consistency similar to baking paper.

Researcher Kehao Huang, postgraduate from School of Chemical Engineering UNSW, told SBS Mandarin that People are over-using plastic materials and producing hundreds of million tons of plastics packaging, which are detrimental to the environment.

"We want to develop biodegradable materials to replace traditional plastic for packaging food in particular. Thus, as a kind of natural polymer, cellulose can be used as a novel food packaging material. The common sources of cellulose are trees and cottons."

"Bananas are a top selling product in the Australian supermarket, contributing to $1.3 billion towards the national economy yearly. Each hectare of the banana crop could generate more than 200 tons of plant residual waste including pseudo-stem. Thus, we decided to extract cellulose from banana pseudo-stem and isolate into nanocellulose. In addition, the smaller particle size can lead to a higher surface area, which can help us to modify its surface properties easily."

"We have been working on the project for the last 5 years with the intention of producing a film that is strong enough to hold a high-mass product, flexible, hydrophobic, and biodegradable. Currently, we are mainly focused on the hydrophobicity of films and have modified the surface characteristics to make films that are more hydrophobic. This is important for packaging food products as water should not be absorbed by the foods making them unsafe."

Mr Huang hope the project can make the banana industries realize the possible applications of banana waste and increase its value.

"The key is in commercialisation of the banana stem powder. It is our hope that the packaging industry will adopt our technology to produce biodegradable packaging for several purposes."

Please see the full report here.

READ MORE

悉尼科技大学研发环保新品:维护高层建筑物的绿色幕墙机械手臂