Highlights

- University of Newcastle claims to develop world’s first non-invasive blood sugar test

- Indian-origin researcher Pankaj Kumar is part of the Australian project

- Test strips may soon enter market, be affordable for poor: Dr Kumar

A team of researchers at the University of Newcastle has recently announced the development of a saliva glucose test, which they claim is the world’s first needle-free blood sugar test.

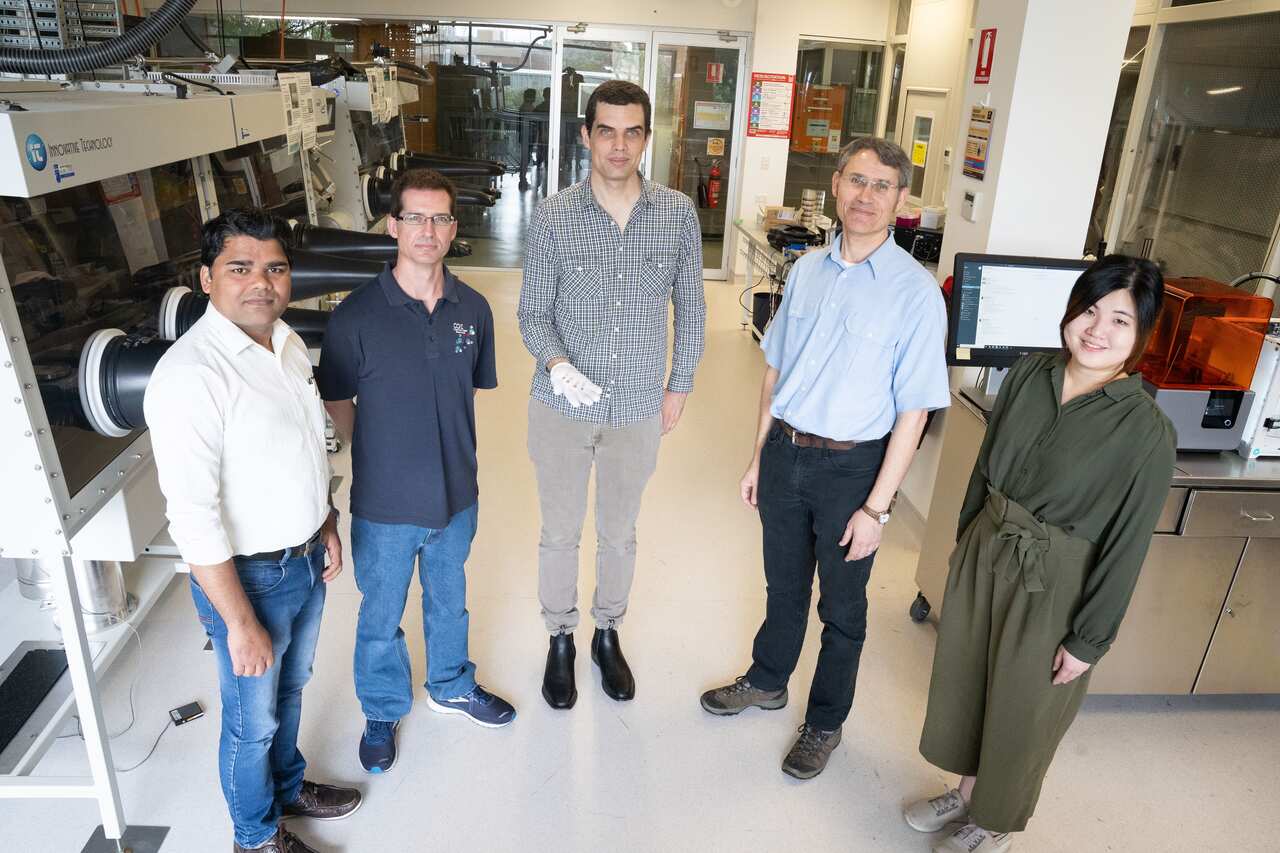

Led by Prof Paul Dastoor, the team included physicists, biologists, engineers and chemists. Mr Pankaj Kumar, an Indian migrant, is the physicist who has put his knowledge of organic semiconductors and devices to use and contributed in making this test work.

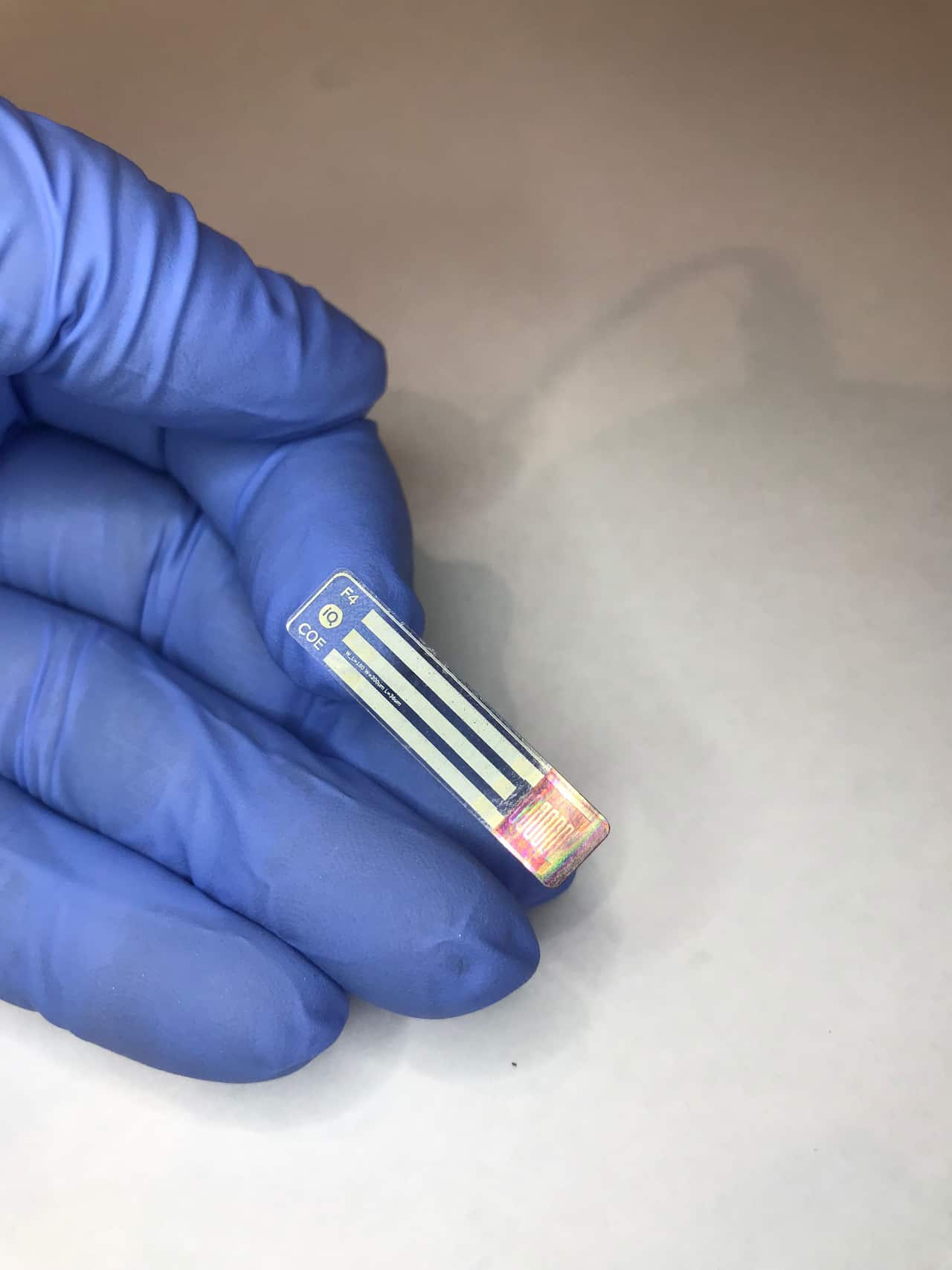

The test is essentially a biosensor – a plastic strip coated with a natural enzyme – which when interacts with saliva, can show accurate glucose levels.

Mr Kumar told SBS Hindi that he fabricated these glucose biosensors and worked on the optimisation of processing conditions, the thickness of different materials and the optimisation of external bias to the sensors to improve their response and sensitivity.

“Being an Indian, diabetes has always been a matter of serious concern for me. I always wished that I could contribute to improving the quality of life of my fellow Indians through science and technology.

“I knew that the Centre of Electronics (CoE) at the University of Newcastle was developing an organic semiconductor-based non-invasive glucose biosensors for diabetic patients, so I wanted to contribute to this technology and develop it as soon as possible as this could also help the Indian people,” Mr Kumar said, highlighting the 2019 data from the International Diabetes Federation that states over 77 million Indians suffer from diabetes.

“I thought my knowledge about organic semiconductors will help develop this technology more rapidly, and indeed it did. I am very happy that soon this technology will be in the market and serve the Australian, Indian and people from other countries in a great way,” he added.

Before working at the University of Newcastle, Mr Kumar worked as a principal scientist at the New Delhi-based National Physical Laboratory, where he researched organic semiconductors and devices for decades.

“I have made a significant contribution in that area. I got my Ph D from the University of Delhi in 2010 for studies conducted on organic semiconductors,” said Mr Kumar, who was awarded the Indo-Australia Early Career Research Fellowship in 2013 for doing research in Australia.

He then joined COE as a visiting fellow under Prof Dastoor’s supervision and started working on the development of organic semiconductor-based solar cells.

“Prof Dastoor already knew my expertise. As these non-invasive glucose biosensors were based on organic semiconductors, he appointed me for the project to accelerate their development,” Mr Kumar said.

Mr Kumar hopes that their teamwork to bring this test into the market becomes a reality soon and also reaches the poor.

“The test strips of non-invasive glucose biosensors are being developed on thin plastic sheets via the conventional roll-to-roll printing techniques using highly cost-effective materials,” he said.

On the production line, roll-to-roll fabrication will lead to the production of hundreds of thousands of sensors in a day and would be significantly cheaper than the conventional strips,” Mr Kumar added.

"These biosensors include multiple layers of different materials playing different roles and when brought in contact with saliva or a solution containing glucose in it, an electrochemical reaction takes place in the sensor that produces charge carriers and leads to the flow of an electrical current,” Mr Kumar explained.

Listing the challenges of the project, Mr Kumar said that making the biosensors sensitive enough to sense the glucose concentration in the saliva and controlling the intermixing of the fabrication were some challenges.

Tune into SBS Hindi at 5 pm every day and follow us on Facebook and Twitter.